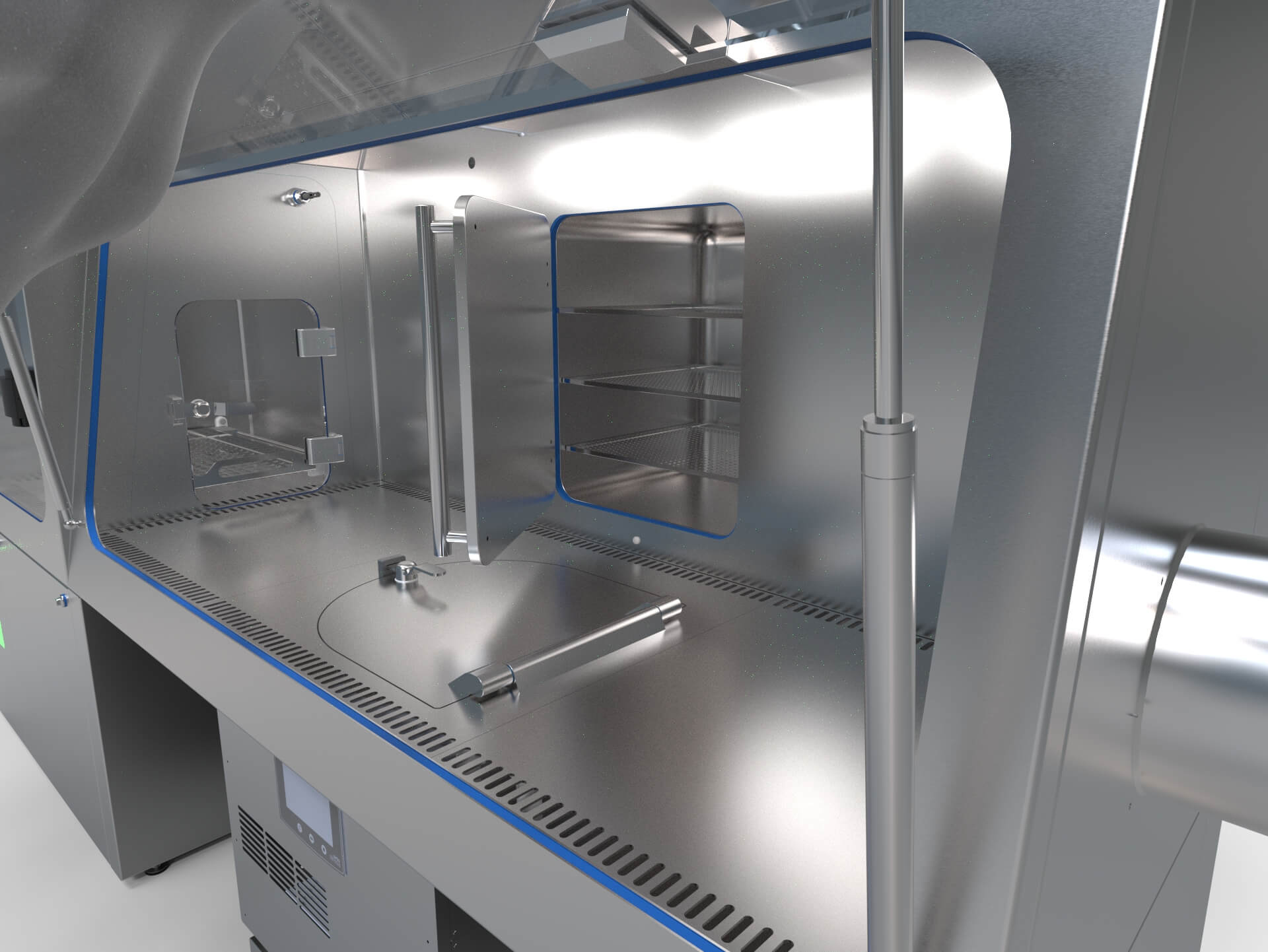

There is a challenge in today’s advanced therapy environment, which is to get your preparations done in a safe environment. At LITEK PHARMA, we have prepared various solutions to enable these production processes to be carried out in a safe aseptic environment, inside the isolator. Compared to traditional clean rooms or laminar flow booths, we offer solutions integrated in isolators for the highest guarantee of process sterility.

LITEK PHARMA’s family of isolators are modularly designed to allow the integration of various laboratory equipment needed to carry out the processes in each of the advanced therapy preparations, such as centrifuges, incubators, refrigerators, gene modification devices and devices for both upstream and downstream cell processing.

LITEK PHARMA’s family of isolators for advanced therapies, have:

Material transfer systems, with integrated VHP disinfection system, enable fast and safe transfer of materials into the isolator, e.g., vials with cells, bottles or IV Bags.

Together with our experts, we also develop all other upstream and downstream processes, including the possibility of implementing the filling of the final preparation in vials, syringes or IV Bags.

Chamber made of stainless steel AISI 316L, 3mm thick, internal polishing Ra<0.6

Compact ventilation module, for recirculation and aeration.

Tempered glass doors with inflatable gasket seal.

Electrical panel incorporated in annex module.

LED lighting

Laminar flow for aseptic processing.

Integrated VHP disinfection system.

H2O2 monitoring, high and low concentrations.

Siemens PLC

Beckhoff HMI industrial PC

Beckhoff 15.6″ touch screen monitor

Integration of laboratory equipment.

Material airlock.

Waste exit port with continuous liner.

RTP (rapid transfer ports) for liquids and solids.

Double HEPA filter H14 impulsion line filtration.

HEPA H14 filter extraction line filtration, close to chamber.

Validatable software 21 CFR Part 11, GAMP5.

Oval gloves

Glove holders for H2O2 disinfection.

Viable / and non-viable particle monitoring.

Catalytic Filter.

Temperature and humidity monitoring.

Temperature and humidity control.

SCADA system.

- User Manual

- Functional Design Specification (FDS)

- Functional Specification (FS)

- Hardware Design Specification (HDS)

- Software Design Specification (SDS)

- Factory Qualification Test (FQT)

- Factory Acceptance Test (FAT)

- Installation Qualification (IQ)

- Operation Qualification (OQ)

- Site Acceptance Test (SAT)

Please do not hesitate to contact us if you require any further information.